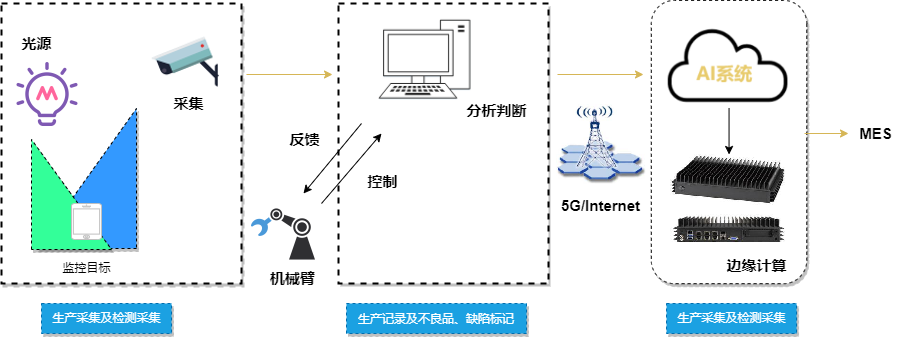

The production and inspection platform of the automated production line is integrated to record the production data in real time, realize the autonomous learning of the detection method and the autonomous optimization of the detection model, completely replace the traditional machine vision of the personnel to re judge the operation, and equip the industry with never tired eyes and brains; The hardware and software can be separated, the hardware can be arranged as needed, and the software can be managed uniformly; Reduce the use cost of visual system and personnel intervention cost; It can realize the inspection process without influence and the automatic separation of good and defective products; Eliminate the impact of detection on the production rhythm and shorten the production cycle.

Based on the end-to-end solution of deep learning, it supports single character multi character annotation and recognition, breaks the technical limitations of traditional methods, and solves complex problems such as curved character recognition, low contrast character recognition, and large character recognition

Positioning and classifying the targets in the tested materials, which is applicable to multiple target detection, small target detection, counting, etc., such as solving the drug pill counting, 3C device detection and other scenarios

Classify and judge the tested materials, such as OK/NG secondary classification of materials, color of tested objects, types of food materials, classification of 3C defects, etc

Fine pixel level detection and edge recognition of detection objects, such as identification of silicon wafer crack area, bearing bruise area, etc

Local/cloud deployment, no need to invest too much hardware in the early stage

Various industry algorithm pipelines are embedded, and partners are supported to develop a common algorithm import platform for the industry